Gravel production process, the material is usually dominated by artificial gravel , natural gravel aggregate supplement , choose artificial gravel material impact on construction equipment construction cost of the project is large, especially in the production of sand and gravel aggregate crushing equipment . There are however lower prices gravel crusher for sale, these gravel crusher production processing capacity is small, and small workshops are some of the processing plant , only applies to some of the channel gravel and sand and gravel aggregate production of small power plants aggregate production , production can not fully satisfy the degree of strength than gravel production system , it can not meet the requirements of high -graded gravel system regulating the production . How to simplify the production process , optimizing the gravel crusher configuration, reduce project costs have been exploring the application.

Traditional aggregate processing systems are multi- stage crushing sand form , the system covers a large , high mechanical configuration , but also need a large workforce , SBM first determined based on the performance of a reasonable size yard situations and equipment gravel system, the system is mainly composed of coarse crushing plant ( including rods tone screening ) , screening workshop , broken shop , sand plant, workshops and semi-finished products inspection screening stockpiles , regulate stockpile , finished aggregate yard, control system and its auxiliary facilities and other components. Were configured devices are jaw crusher, impact crusher , cone crusher, sand making equipment shaker optimal allocation , using a closed-loop segments , namely crushing and screening closed loop , sieve sand and inspection of closed loop . According to the different periods of production plans to adjust its equipment discharge port opening, to screening workshop reversible tape machine acting as intermediaries adjustment mechanism to meet the coarse aggregate or sand material demand, especially sand and efficient process using sand machine, crushing sand will be completed , the process is complete the entire gravel processing system , rational , process design, especially gravel crusher application , temporary construction not only reduces investment costs , but also reduces the cost of production.

gravel stone mining production system at any time according to the material properties of the field of physics , technology and system design requirements , combined with gravel crusher broken particle size characteristics of the product . Optimize the allocation of the workshop equipment , the rational allocation of machinery and equipment to achieve the best mechanical efficiency , improve system assurance capabilities. Aggregate processing system is reliable and reasonable production equipment configuration, bold and innovative production process design, in complex natural conditions , using advanced computer control technology to achieve a large-scale construction system automation and centralized monitoring, to provide a high level of finished aggregate were fully guaranteed. Aggregate demand of market , sand quality is ever increasing, the corresponding auxiliary enterprises, especially aggregate processing system put forward higher requirements.

Gravel (pebble)

It is suitable for construction applications in cement concrete, asphalt concrete and various stabilized soil, and also for highway engineering applications in road, tunnel, bridge and culvert, etc.

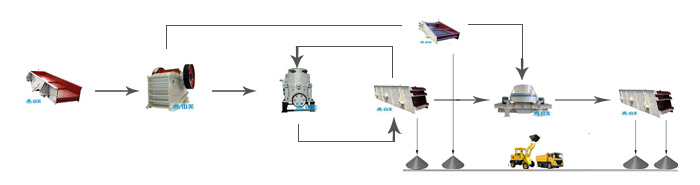

Feeder, vibrating screen, cone crusher, sand making machine, belt conveyor, sand washer.

The gravel resource in China is abundant, the main chemical composition of gravel is silicon dioxide, secondly it is composed by small amount of iron oxide and trace elements such as manganese, copper, aluminum, magnesium and compound, it has natural stone features of hard quality, compression, wear-resistance and anticorrosion, it is an ideal material for building application. Currently gravel sand making production lines are continually built all over the country, which guarantee the supply of quality aggregate for national construction projects.

0-40mm crushed stone (pebble) is used as raw material for gravel production line, vertical shaft impact crusher (sand making machine) is adopted by the production line, this crusher is a new type sand making machine of Sanme, which has the features of high crushing efficiency(offering fine crushing and coarse grinding), simple structure, easy maintenance, low operation cost and excellent particle size(cubic shape, low content of needle-like particles).

Gravel resource in our country is abundant, and varies from place to place. Wear resistance is firstly considered when selecting equipments. The stone with big grain will be crushed with reference to the crushing of granite and basalt; the stone with small grain will be screened in advance to reduce the production cost;

Taking the gravel with grain less than 200mm as an example, the material will be transported by feeder and belt conveyor from hopper to 1# vibrating screen for pre-screening, the material with grain larger than 40mm will be conveyed into cone crusher for crushing, the material with grain of 5-40mm will be conveyed into vertical shaft impact crusher for crushing, the material with grain of 0-5mm will be washed by sand washer and will be discharged as final product. The product after being crushed by cone crusher will be conveyed to 2# vibrating screen, the material larger than 40mm will be conveyed to cone crusher for crushing again, to achieve a closed circuit, the material less than 40mm will be conveyed to vertical shaft impact crusher for crushing, the material after being crushed by vertical shaft impact crusher will be conveyed to 3# vibrating screen for screening, the material larger than 20mm will be conveyed back to vertical shaft impact crusher for crushing, to achieve a closed circuit, the material less than 20mm will be conveyed by belt conveyor to final product pile, according to the cleanness of the material, it is considered that 0-5mm material may be washed by sand washer.

The sand making production line has the features of reasonable configuration, high automation, low operation cost, high crushing rate, energy saving, environmental protection, high capacity and easy maintenance, the manufactured sand conforms to national standard for construction sand, uniform grain, excellent particle size, well graded.

The equipments of the sand making production line are configured in accordance with the specification and output as well as application of the sand, we provide solution and technical support, and design the process according to the production site of customer, we make every effort to provide the most reasonable and economic production line for customers.